Do you want to print a bag with glossy and shiny effect?

To make your different bags more shiny, the most important thing is to get the right material and print glossy ink with laminating and varnishing process on bags. So that you will get a bright printing bags with your designs.

1.Paper bags

Natural kraft paper are most popular for foods or high value products bags printing. With raw kraft paper, you can’t make it glossy and attractive, you need add with a film outside to make it smoother and lighter, which we called it lamination. Choose high-gloss and quick-drying ink to improve hiding power and gloss.

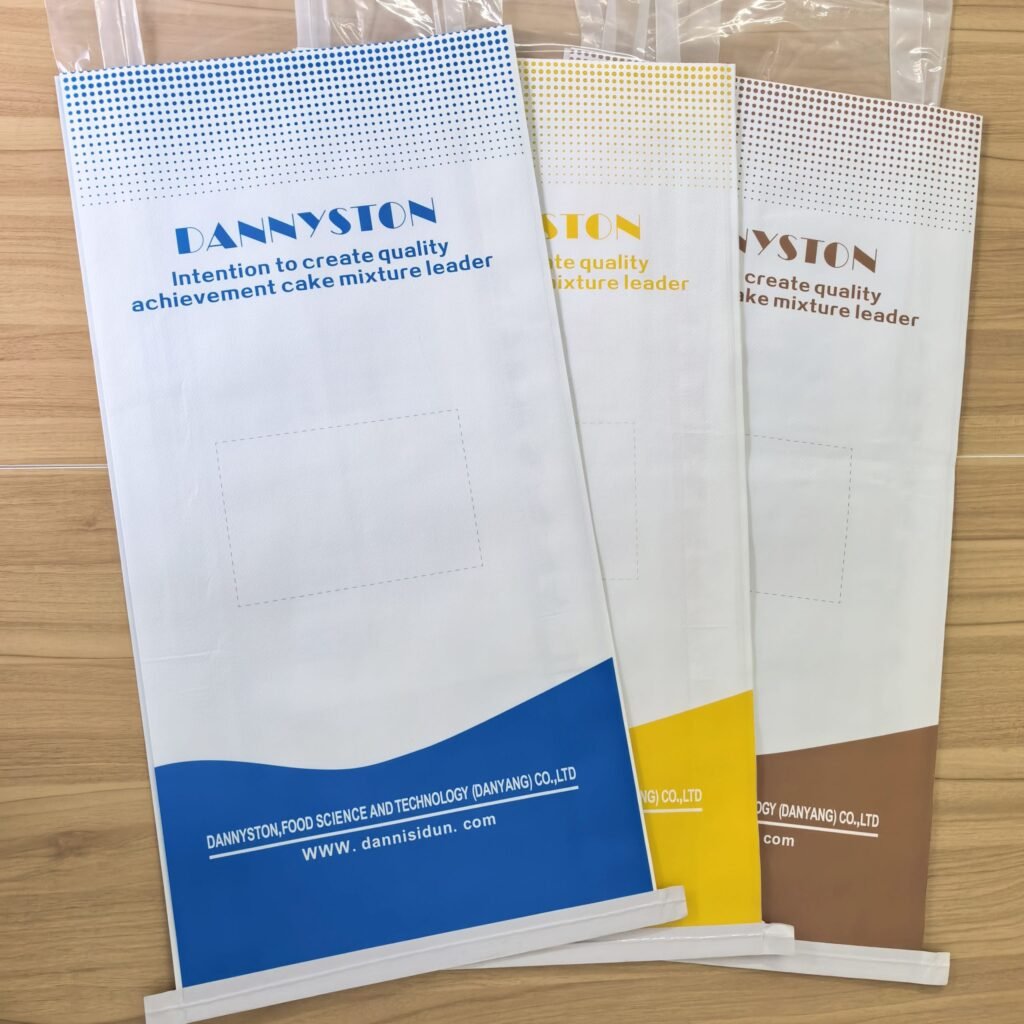

2. Plastic bags PP woven bags PE bags

PP woven fabric laminated glossy bopp film bags are very soft and widely using for chemical, rice, grain. You can print your logo, your products with gravure printing machine and show colorful items on the bags surface. Laminated bags are also water proof for storing and transportation. Plastic packaging bags use high-gloss plastic inks, whose resin components can form a high-gloss film on the plastic surface, making the finished package bags glossy and not easy to fade. That will be more exquisite and excellent products to compare with your competitors.

3. Plastic bags flexible PE package bags

Flexible package bags are made of multi-layer materials such as PE PA OPP PP Aluminium PET BOPP and other materials, which used for foods, animal feeds, pet foods packing bags. The most used material for glossy printing is BOPP and PET film. These two material is outer layers for digital and gravure printing effect. After covering, it can form a mirror-like gloss, while protecting the printed pattern from wear and water. Also, you can highlight the design with Gold plating process and UV laser. That’s the regular operation for soft PE bags to be glossy Package bag!

Which kind of bags you used now? Let us discuss for more glossy package bag!