kraft paper flour bag is very popular used for flour packaging. It is my 12th year in the custom packaging bag business. I still remember my first sea freight order five years ago. It was from a Romanian woman who was looking for 1kg bags of kraft paper flour bag. Her flour was a healthy type, meant to aid in weight loss. After our conversation, I learned she wanted 10,000 kraft paper flour bag, with two designs already completed, and she wanted 5,000 of each.

After detailed calculations, I suggested she buy 30,000 bags directly, as the kraft paper flour bag unit price would be much cheaper, and the sea freight volume would be exactly one cubic meter. At that time, I didn’t know what would happen with sea freight. If it were now, I would definitely offer her a DDP (Delivered Duty Paid) door-to-door delivery solution, but unfortunately, I didn’t know much about sea freight then, and no one in my company had ever done DDP door-to-door delivery for clients.

There are generally several types of materials that can be used for flour bags:

2. PE composite flour bags

3. Paper composite PP woven flour bags

4. BOPP composite PP woven flour bags

For this client, who only needs to store 1kg of flour, kraft paper bags or PE composite bags are the most common choices. Since the client is from a European country and places greater emphasis on environmental protection, single-layer kraft paper bags are more suitable. Therefore, I sent the client 30,000 kraft paper flour bags, along with two different printed proforma invoices (PIs) for 15,000 kraft paper flour bag each. She quickly transferred the prepayment via bank wire transfer. After carefully reviewing the design and layout, we placed an order to produce both types of flour bags.

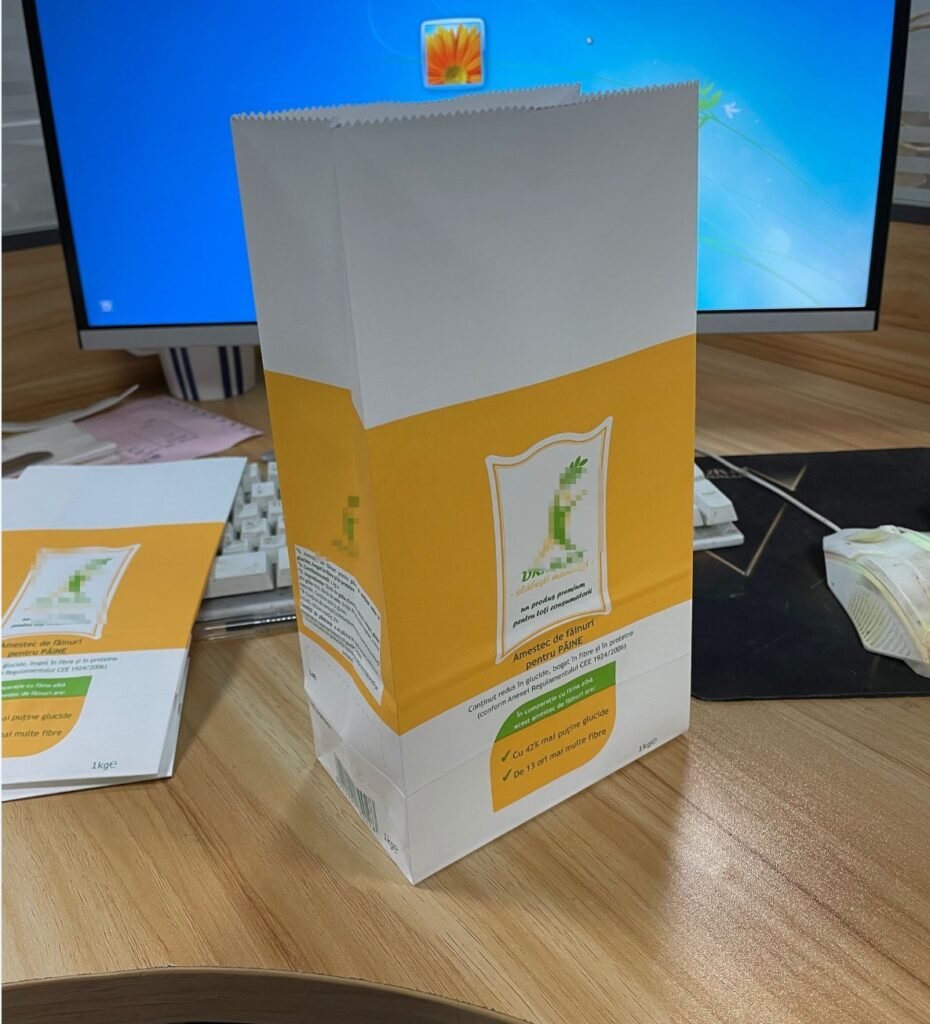

The bags turned out beautifully; the client’s design had excellent color matching, was very attractive, and was immediately recognizable as flour bags. During production, I took photos and videos and sent them to the client. When the flour bags were finished, I sent her photos and videos of the completed bags. She was very satisfied with the bags and quickly paid the remaining balance.

Next, I started booking shipping space, and everything seemed to be going smoothly. After about 50 days, the customer messaged me saying the goods had arrived at the port of Constanta and that a high destination port charge was now required, along with an invoice. At the time, it was my first time dealing with ocean freight, and I didn’t know what this destination port charge entailed. After some learning, I understood that for LCL (Less than Container Load) shipments, in addition to the ocean freight, upon arrival at the destination port, besides customs duties, there are also charges such as terminal handling fees, unloading fees, unpacking fees, port storage fees, and documentation fees.

Therefore, when your order has a small volume of goods, you should definitely consider having your supplier quote a DDP (Delivered to Door) price instead of CIF or CFR to a specific port, because the DDP price includes everything, allowing you to know the total cost and whether you can afford it.

Next, my customer informed me that the customs duties plus the destination port charge were very high, and she even considered abandoning the shipment. After repeated discussions and consideration, our company ultimately covered part of the cost for the customer, and she took delivery of the goods. Although the goods were received and the quality was satisfactory, the customer’s experience was not particularly good.

Therefore, as a salesperson, one not only needs to be familiar with the product but also with the shipping process, and possess a strong sense of responsibility and excellent problem-solving skills for unexpected issues. As a customer, when selecting a supplier, in addition to considering price and delivery time, one should also consider whether the salesperson is responsible and has sufficient experience.