Charcoal bags customized must complied with new charcoal exporting rule. What are the new requirements and key considerations for exporting raw hardwood charcoal, briquette charcoal, Coco nut charcoal in November 2025? What is UN 1361 and its specific requirements? What kind of charcoal package bag shall we use for UN 1361?

Are hardwood lump charcoal, coal briquette charcoal, and coconut shell charcoal classified as dangerous goods? What type of packaging bags are required for exporting coal charcoal to comply with regulations?

“UN” stands for the United Nations. This numbering system was created by the UN to provide a unified identification standard for the global transport of dangerous goods. In any country, seeing “UN 1361” immediately alerts all personnel involved in transport (such as dockworkers, crew, freight forwarders) that this is charcoal, belonging to Class 4.2 dangerous goods, and must be handled according to specific rules. Is charcoal (UN 1361) a dangerous good? Charcoal is classified as a Class 4.2 dangerous good primarily due to its “liable to spontaneous combustion” nature. The applicable packing group is III, indicating lower danger.

Regarding the new UN 1361 dangerous goods package bag export regulations, they were proposed by the International Maritime Organization (IMO). Voluntary compliance starts 1 January 2025, with mandatory enforcement from 1 January 2026, for new regulations. Famous vessel companies such as Maersk and MSC will enforce full compliance on a mandatory basis starting 1 November 2025 (ahead of the IMO mandatory date).

So, what needs attention when transporting charcoal? Maersk and MSC have provided more specific requirements:

1. Charcoal must be declared as DG under UN1361/4.2 with Proper Shipping Name as CARBON, animal or vegetable origin.

2. Packing & Stuffing: Allowed in UN approved Boxes, Bags, Drums and IBC as per P002 packing instructions of IMDG code 42-24. Not allowed in packings of 4H1, 5H1, 5H2, 5L1, 5L2, 5M1. Every shipment of charcoal must be completely vacuum packed with a thermal jacket.

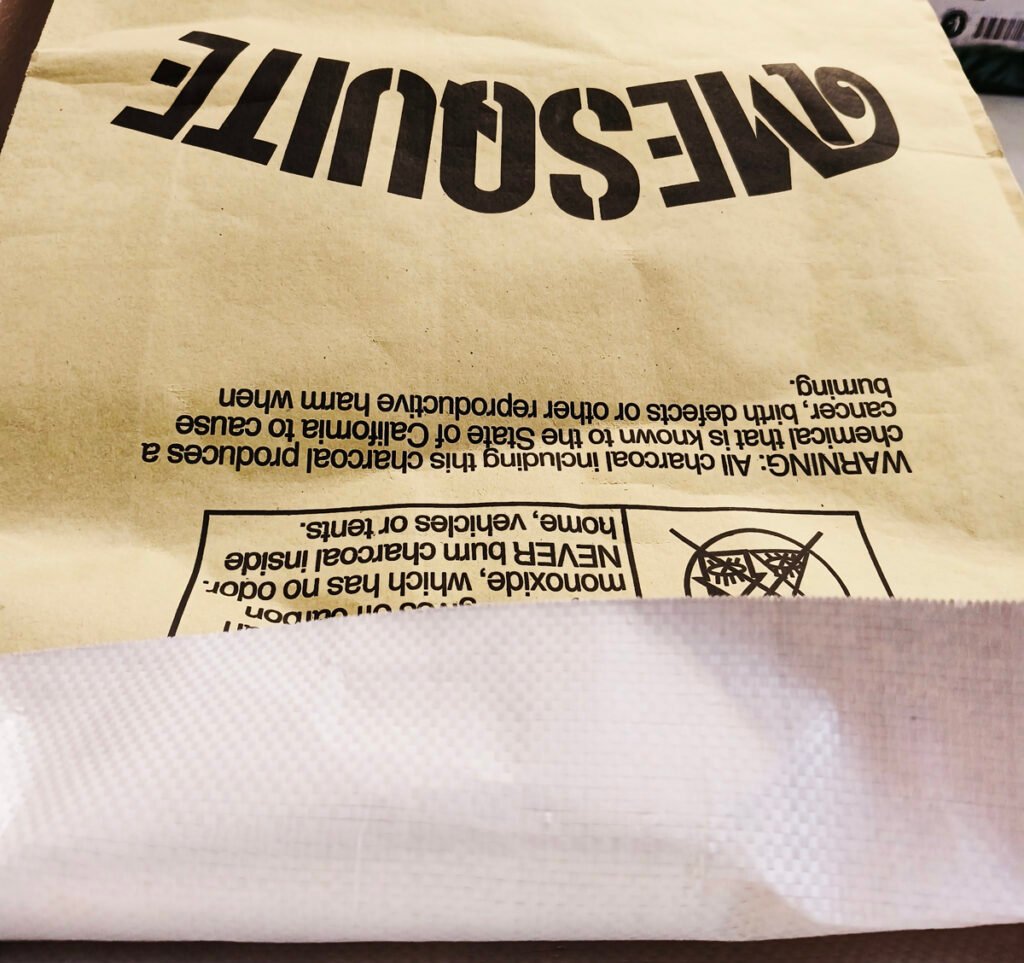

Additionally, the bags containing the charcoal should be printed with corresponding dangerous goods marks and labels. Both sides of the container also need corresponding dangerous goods placards and labels, which must be large and conspicuous.

What needs attention in the process of exporting charcoal?

Details of documents:

1. Material Safety Data Sheet: It must indicate the use of the charcoal and must be from the same entity (producer/Manufacturer of Charcoal).

2. Dangerous Goods Declaration and Packing Certificate: as per chapter 5.4 of IMDG code.

3. Weathering Certificate: On company letterhead; dated, signed and stamped; to be issued by the manufacturer (real producer of the cargo) with the following:

●Dates: Date of issue of cert, date of Production, start and end date of weathering, start and end date of packaging.

●Photos: (The photos must be clicked straight and not at any other angle.) Weathering process, packaging process, temperature of cargo while packaging.

●Details: Booking number and container numbers, details of packaging (weight, size, type etc…), Charcoal particle size in mm and type of Charcoal (briquetted or non-briquetted hardwood, coconut shell, palm kernel shell, rice husk, coconut charcoal, sawdust, Sisha, etc…)

●Confirmation:

●Confirming that after production, the unpacked material was subject to weathering (stored under cover, but in the open air) for a minimum period of 14 days before being packaged for transport. (Under circumstances where the manufacturer is unable to achieve a minimum of 14 days of weathering; an approval by the competent authority shall be obtained and submitted along with the weathering certificate and a declaration stating the reason for not achieving 14 days of weathering).

●Confirming that while the material was packed into packaging the temperature of the material did not exceed 40°C.

4. Vanning Certificate (Vanning survey report is acceptable only from Maersk nominated Surveyors.):

●Dates: Date of issue of cert, start and end of Vanning.

●Photos: (The photos must be clicked straight and not at any other angle.)

●Container stuffing process, incl. minimum one photo of the cargo without the outer packing.

●Cargo temperature and Ambient temperature photographs of each container.

●Thermal jacket in completely vacuumed condition.

●One door shut photograph such that the commodity stuffed inside the container and container number are clearly visible. (Complete container must be visible along with its border and edges)

●Both door shut with seal and with visible seal number.

●Details: Booking number and container numbers and their seal numbers, details of packaging (weight, size, type etc…), Charcoal particle size in mm and type of Charcoal (briquetted or non-briquetted hardwood, coconut shell, palm kernel shell, rice husk, coconut charcoal, sawdust, Sisha, etc…)

●Confirmation:

●Confirming each container with number that it is completely Vacuum packed with a Thermal Jacket supplied by Shipper’s preferred Maersk Recommended Supplier (Supplier name).

●Container is packed, Labelled and placarded in accordance with packing(P002), SP978, chapter 5 of IMDG code 42-24 and CTU packing guide.

●Packings are new, air tight, intact and suitable for the cargo.

●Temperature of cargo is not exceeding ambient temperature by more than 5°C.

●Packaging and interior atmosphere is clean and odorless, no presence of fumes or smoke.

What are the requirements for dangerous good charcoal bags during export?

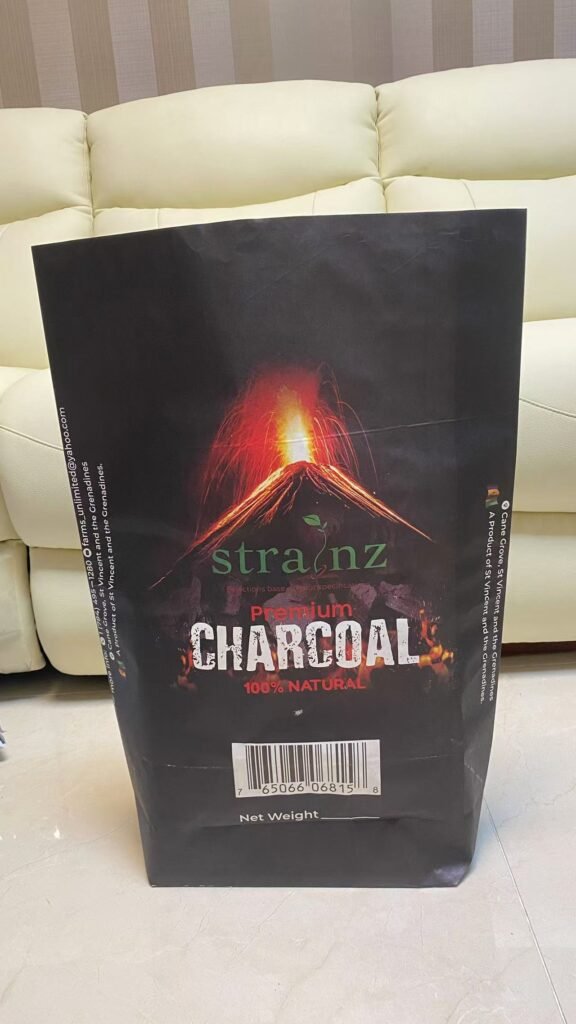

Here are examples based on commonly used charcoal bags. According to the new regulations, the following bag materials can continue to be used:

1. BOPP composite PP woven charcoal bags (5H3 type)

2. Paper laminated PP woven charcoal bags (5M2 type)

3. Multi-layer paper + PE laminated charcoal bags (5M2 type)

Bags explicitly no longer permitted include pure PP woven charcoal bags (5H1 type, non-composite PP woven), laminated PP woven bags (5H2 type), and pure paper bags (5M1 type).

Do the coal bag as dangerous packaging need specific markings?

Yes, the packaging bags for Class III dangerous goods hardwood lump charcoal need to be printed with the UN code (the dangerous goods packaging code held by the certified manufacturer) and the dangerous goods symbol. Depending on the bag size, the symbol size must meet specific requirements.

What treatment do the bags need before filling with charcoal?

After production, the unpacked material shall be stored under cover, but in the open air (weathering) for a minimum period of 14 days before being packaged for transport. Some clients leave the bags uncovered and exposed to the sun, making the bags fragile and easily broken.

I STILL HAVE A STOCK OF NON-UN APPROVED BAGS, CAN I STILL USE THEM?

Yes, you are allowed to still use them under the following conditions.

1) The bags are:

a) Sift-proof

b) Hold a maximum of 50 kg per bag

2) The bags are packaged in a UN approved outer packaging; the max cargo net weight per outer packaging is 400 kg. Some examples of outer packaging include plywood box 4D or fibreboard box 4G.

If you want to learn more about the UN 1361 new regulation and customize compliant package bags for charcoal, please feel free to contact us on WhatsApp at +86 18028684546. We are UN certified package bags factory in China.