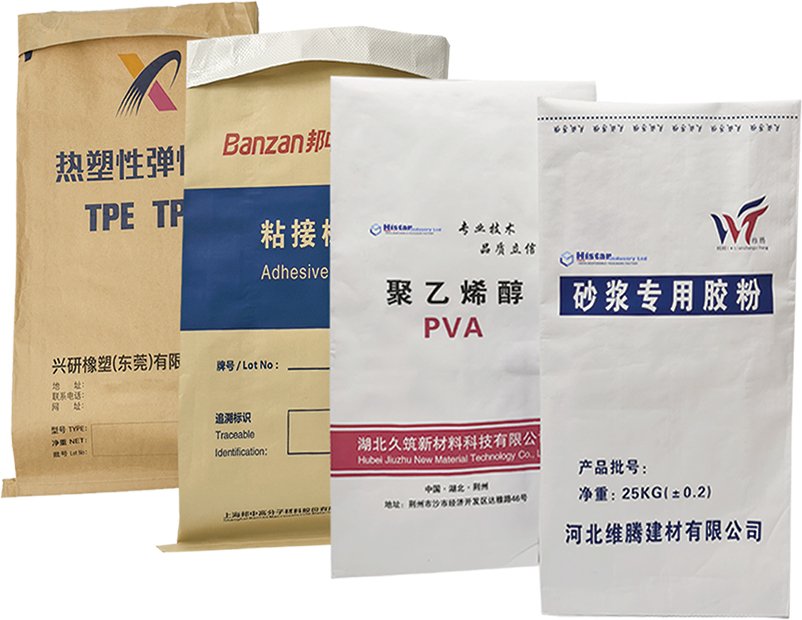

Powdered Chemical Package Bags: From Leak Prevention to Freshness Preservation, These Details Determine Safety and Quality.

For powdered chemicals, the choice of chemical package bags directly affects product purity, transportation safety, and shelf life. Unlike liquid or solid block chemicals, powders are prone to moisture absorption, dust generation, and static electricity generation due to friction. This requires packaging bags to precisely meet the three core requirements of “sealing, anti-static properties, and load-bearing capacity.”

Material Selection: Matching Materials to Specific Needs is Key.

The differences in the properties of powdered chemical package bags mean that a one-size-fits-all approach cannot be applied to the selection of packaging bag materials, and choosing the right material is the first step to avoid contamination and powder leakage.

- Ordinary non-corrosive powders (such as industrial-grade calcium carbonate and baking soda): Polyethylene (PE) bags are the first choice. They are highly tough, capable of withstanding regular storage and short-distance transportation. They can also effectively isolate external moisture and prevent powder caking.

- Powders requiring oxygen/light isolation (such as catalysts and food-grade additives): Aluminum-plastic composite bags are a must. The inner aluminum foil forms a “vacuum protective layer”, which completely blocks oxygen and light, preventing the powder from oxidative deterioration or reduced activity. Many high-end powdered chemical products adopt this composite protective packaging.

- Powders containing trace corrosive substances or prone to moisture absorption (such as some inorganic salt powders): Polypropylene PP woven bags or multi-layer co-extruded film bags are recommended. The chemical resistance of PP material is better than that of PE, and the multi-layer structure can further enhance moisture and penetration resistance, reducing chemical reactions between the powder and the powder chemical packag bag.

2. Core Design: Small Details Solve Major Problems.

The “pain points” of powdered chemical package bags mainly focus on powder leakage, dusting, and static electricity, and targeted design is the key to solving these problems.

- Sealing method: For ordinary powders, a “heat seal + zipper” design can be used to facilitate secondary use. For high-purity or moisture-absorbing powders, three-layer heat-sealed edges are essential to ensure no pinhole leakage at the bag mouth. Some customers will also add an additional sealing tape to enhance sealing performance.

- Anti-static plates: Powders are prone to generating static electricity due to friction with the bag wall during transportation, which may pose safety risks. Therefore, the inner side of the packaging bag needs to be coated with an anti-static layer or have a built-in anti-static film to discharge static electricity. This is especially applicable to flammable and explosive powders (such as some metal powders).

- Practical structure: The “square folded side” design at the bottom allows the bag to stand independently, facilitating filling, storage, and stacking. A tear strip is reserved on the bag body to avoid powder splashing when using scissors. It can also be made into a valve top design for quick bagging, improving efficiency and reducing packaging bag damage.

3. Compliance and Environmental Protection: Unignorable “Invisible Requirements”

Packaging bags for powdered chemical products must not only meet usage needs but also comply with industry standards and environmental protection requirements.

- Compliance: They must pass the tests specified in the national General Specification for Solid Packaging Materials of Chemical Products, including the drop test (no damage when dropped from a height of 1.2 meters) and the load-bearing test (load-bearing capacity is more than 1.5 times the weight of the product). The bag surface must clearly print the product name, ingredients, moisture-proof/anti-static marks, and production batch number to ensure traceability.

- Environmental protection: Recyclable PP/PE materials have become mainstream. For food-grade powder packaging bags, they must also comply with the safety standards for food contact materials to ensure no migration of harmful substances.

Choosing the right packaging bag for powdered chemical products is essentially creating a “customized protective shield” for the product. Whether it is material, design, or compliance, precise control of every link can effectively reduce losses and improve safety factors.

Do you need me to organize a bag for your chemical powders? Click here to meet us for more!